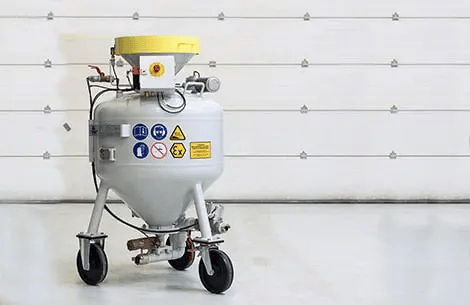

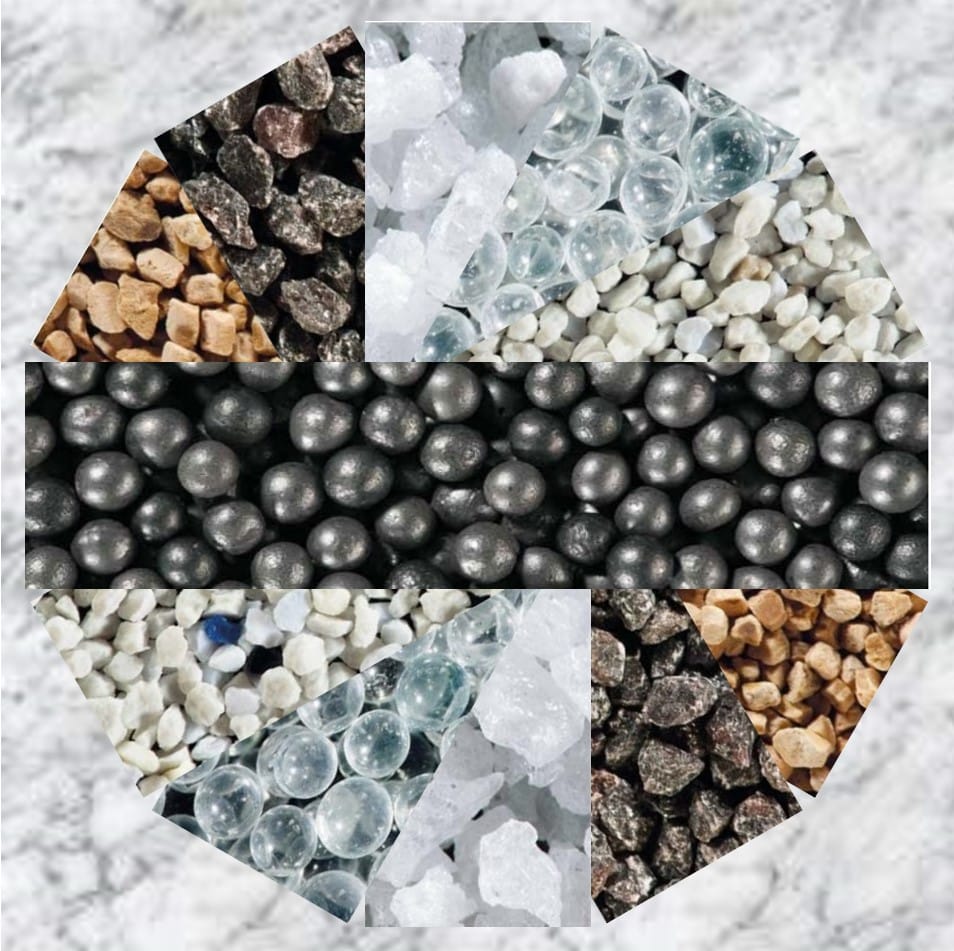

Sugeudstyr, sandblæsekabine, sandblæseudstyr og blæsemidler tilbydes i Odense

Clean Blast ApS har med mere end 30 års erfaring indenfor industrisugesystemer, sandblæseanlæg og sandblæsemidler. Vi leverer løsninger til næsten alle typer virksomheder, fra små til store samt fra den sorte jernindustri til pharmaindustri. Vi lægger stor vægt på den personlige kontakt, for der igennem at servicere vores kunder på bedste vis.

Hos os er I altid sikret den bedste løsning

Vi ønsker at give vores kunder de bedste løsninger med udgangspunkt i netop jeres aktuelle behov, og med baggrund i vor mangeårige erfaring. Vi samarbejder med jer om at nedbringe jeres omkostninger og optimere jeres nuværende løsninger/systemer. Vi kommer gerne og gennemgår jeres nuværende system helt gratis.